The triangle of color

Color exists due to the interaction of light sources, objects, and the human visual system. Color is an attribute of visual sensation, and the color appearance of objects depends on the three components in the triangle.

The first component is a source of visible light energy necessary to initiate the sensory process of vision. This energy is then modulated by the reflection or transmission properties of an object. The modulated energy is then sensed by the eye of the human visual system to produce our perceptions of color.

Light sources are quantified through their spectral power distribution and standardized as illuminants. (Standard Illuminants, also known as Norm Light)

Material objects are specified by the geometric and spectral distribution of the energy they reflect or transmit.

The human visual system is quantified through its color matching properties that represent the first stage response (photopigment absorption) in the system.

Since reflectance feature of objects and color perception of eyes do not change during short time, a reliable norm light source becomes necessary.

Standard lighting (Norm light) is needed for color management

When an object is being observed by the human eye, its color is a result of the surrounding lighting conditions and the reflection of the object. Combined with the complex nature of the human eye, the slightest variation in lighting and environment can produce significant color difference. An object may appear entirely different in different environments. For industries that require consistent color appearance of the materials or products between all participants in the supply chain, the best way to guarantee that is to make sure that all colors are viewed in a strictly controlled environment that is built in line with industry standards. Therefore standards are required and thus established by respective industries for color viewing and color assessment.

Before the standard was established, every participant in the supply chain is using different light sources. Each was seeing a different presentation of the color when viewing the product. Now with the industrial standards, everyone is seeing the same color out of the product.

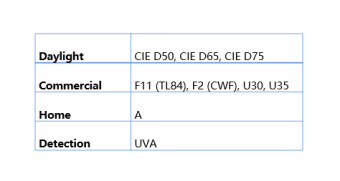

Major lighting modes for color and appearance viewing

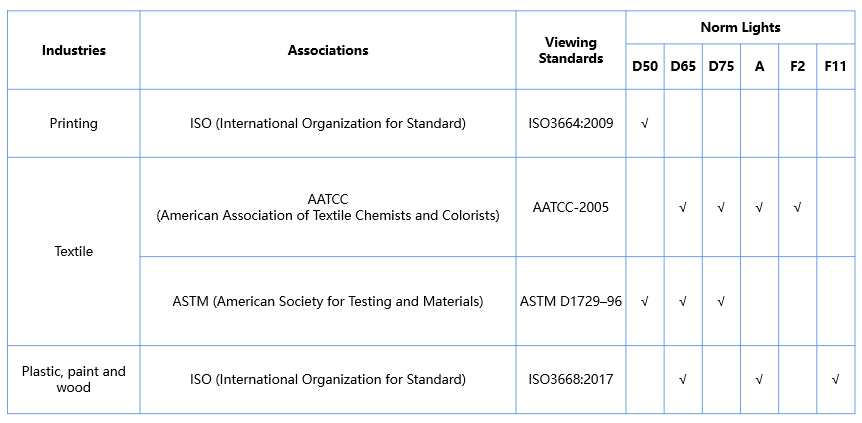

Major industrial standards for color viewing conditions

D50 - Standard illuminant for printing industry & graphic arts

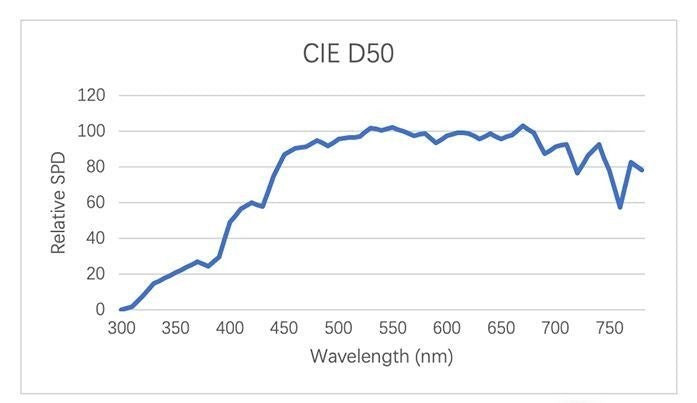

Since D illuminants are based on the daylight curve that runs above the blackbody, D50 has a spectral energy distribution that closely matches that of a blackbody at 5000K. The printing and graphic arts industries have adopted ISO 3664:2009 “Graphic technology and photography– Viewing conditions” standard that specifies D50 daylight viewing conditions.

The standard regulates the viewing conditions for the color proofing of originals and reproductions in the printing and graphic arts industries. It specifies the requirements for color quality, light intensity, evenness of illumination, evenness, surrounding conditions and geometry. Differences in any of these aspects may have great impacts on the color observation and final appearance of the object. It helps engineers and manufacturers in the printing and graphic industries to design, evaluate, and certify their color viewing and assessing systems and helps reduce errors, control quality, and improve color communication.

The standard provides a specific spectral energy distribution between 300 nm and 780 nm for the D50 standard light source.

Distribution of Standard Illuminant D50

ISO has specified the standard light source for the graphic technology and photography industries, defining five conditions. This set of specifications are used to help lighting manufacturers design, test and certify color viewing systems to ensure accurate color reproduction. The light sources must meet the following technical conditions per the ISO 3664:2009 standard.

1. Color Quality

A) Color Rendering Index (CRI)

Color Rendering Index (CRI) measures the ability of a light source to accurately reproduce the colors of the object it illuminates. The general CRI (Ra) should be 90 or greater. The CRI value of each individual color sample (Ri) should be 80 or greater.

B)Color temperature

The color temperature of a light source should be about 5000K.

C)Chromaticity

The chromaticity coordinates should be within a 0,005 radius of the D50 chromaticity coordinates (u’10=0.2102, v’10=0.4889). The metamerism index: MIvis should be less than 1.0, Mluv should be less than 1.5 (level C or higher)

2. Intensity of illumination

ISO 3664:2009 recommends an ideal illumination level of 2000 ± 250 lux on the observation surface. ISO 3664:2009 recommends a minimum illumination level of 2000 ± 500 lux on the observation surface.

3. Evenness

For reflective viewing: the minimum luminance at the edge should be at least 75% of the full central luminance when the viewing surface is less than 1 square metre. The minimum luminance at the edge should be at least 60% of the full central luminance when the viewing surface is greater than 1 square metre.

4. Surround condition

Reflective viewing environment: the walls, ceilings, floors and other surfaces of the viewing environment should be painted a neutral matt grey, with luminous reflectance of less than 60%.

5. Lighting geometry

Light source, image, and observer’s eyes positioned such that specular reflectance (glare) is minimized.

Basic requirements of ISO3664:2009 color viewing standard for graphic arts:

a. Chromaticity coordinates ≤ 0.005 radius of the D50 coordinates (u’10 = 0.2102, v’10 =0.4889)

b. Color temperature = 5000K

c. Color Rendering Index (CRI) ≥ 90

d. Light intensity: 2000 lux ± 500 lux

e. Transparencies: 1270 cd/m2 ± 320 cd/m2

f. Evenness ≥1200 lux (60% of 2000 lux) on the whole viewing surface

g. MIvis< 1.0 (Metamerism index VIS)

h. MIuv< 1.5 (Metamerism index UV)

6. Metamerism

Metamerism describes the phenomenon that occurs when two materials or objects match under some lighting conditions but not under others. Industries dealing with textile, paint, automotive, plastics, packaging, and print may be affected by this when combining different materials or materials from different sources into one product. The Metamerism Index (MI) is derived by calculating the color difference of eight metamers (five in the visible spectrum and three in the ultraviolet range) in CIELAB or CIELUV. It tells how well the samples match under the test and reference illuminant. MI can be decomposed into MIvis (visible light) and MIuv.

NormLite™ D50 Pro LED lights (ISO3664:2009)

Yuji Lighting NormLiteTM CIE D50 (Daylight 5000K) Pro LED lights provide industrial standard daylight solutions after CIE standard illuminant series D. These lights could create an ideal viewing condition in compliant with ISO3664:2009 standard for graphic arts. Featuring in CRI 97+, Grade B or C Metamerism Index visible (MIvis) & UV (MIuv) and 20,000 hours spec lifetime, they are preferable for direct replacement for fluorescent bulbs in color viewing booths and color viewing cabinets in printings. These lamps are able to be approved for certification for lighting conditions by Fogra PSO, UGRA and G7.

NormLite™ D50 Basic LED Lights (ISO3664:2000)

Yuji Lighting NormLiteTM CIE D50 (Daylight 5000K) Basic LED lights provide industrial standard daylight solutions after CIE standard illuminant series D. These lights could create an ideal viewing condition in compliant with ISO3664:2000 standard for graphic arts. Featuring in CRI 97+, Grade B or C Metamerism Index visible (MIvis) and 30,000 hours spec lifetime, they are preferable for direct replacement for fluorescent bulbs in color viewing booths and color viewing cabinets in printings.

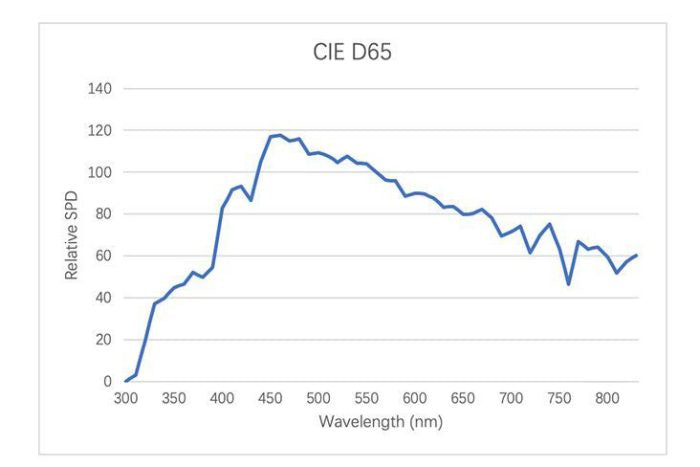

D65 - Standard illuminant for industrial color assessment

Similar to D50, D65 refers to a standard illuminant of 6500 K, defined by ISO 3668 “Visual comparison of the color of paints”. The standard describes all the parameters required to ensure color viewing and matching, such as viewing and ambient conditions. By definition, the CIE and ISO state that the “CIE standard illuminant D65 should be used in all colorimetric calculations requiring representative daylight, unless there are specific reasons for using a different illuminant.”

Distribution of Standard Illuminant D50

It is mainly applied in all manufacturing industries that have sample or product color evaluation process involved, no matter they are materials, surfaces, or finishes. The countless applications D65 standard serves include:

- a. Automotive accessories and interior parts

- d. Food processing

- c. Agricultural product quality

- d. Pharmaceuticals

- e. Chemicals

- f. Furniture

- g. Coatings and finishes

- h. Plastics

- i. Textiles and leather

Similar to D50, D65 refers to a standard illuminant of 6500 K, defined by ISO 3668 “Visual comparison of the color of paints”. The standard describes all the parameters required to ensure color viewing and matching, such as viewing and ambient conditions. By definition, the CIE and ISO state that the “CIE standard illuminant D65 should be used in all colorimetric calculations requiring representative daylight, unless there are specific reasons for using a different illuminant.”

NormLite™ D65 Basic LED Lights (ISO3668:2017)

Yuji Lighting NormLiteTM CIE D65 (Daylight 6500K) Basic LED lights provide industrial standard daylight solutions after CIE standard illuminant series D. These lights could create an ideal viewing condition in compliant with ISO3668:2017 standard for color matching. Featuring in CRI 97+, Grade B or C Metamerism Index visible (MIvis) and 30,000 hours spec lifetime, they are preferable for direct replacement for fluorescent bulbs in color viewing booths and color matching cabinets. These lamps are also in compliant with ASTM D1729–96, AATCC-2005 and DIN6173 standards for surface and critical color viewing and color matching.